Part Marking

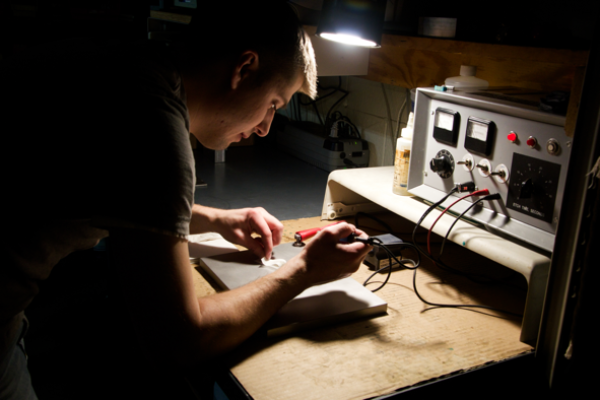

Electrochemical

Our portable etching system uses an electric current to create a mark.

Able to create alphanumeric identification, Data Matrix codes and logo designs, it is often used for small to medium production runs of aerospace components. This process is ideal where tight tolerances over surface treatments exist.

Laser

The laser marking process is ideal for marking all metals, carbides, painted/anodized materials, and most plastics. This process offers programmable character size and depth as well as automatic serialization and date coding. Laser marking inscribes human readable as well as data matrix information. 4th axis rotary (up to 360°) available as required.

Stamping

As necessary per customer requirements.

Dot Peen

Dot peen marking is an economical, low-stress process that creates permanent marks. Programmable character size and depth along with automatic serialization and date coding are available with this process.

Vibro Peen

Both programmable and manual Vibropeen are available with pneumatically fired pins. The stylus can do a test run following the outline of each line to be marked to allow for proper placement of the marking. This process allows for deep incisions and lends itself to special applications such as: marking in straight line at any angle of inclination, in a circle, programmable home positions, centers, radii and orientations of the characters. Vibropeen can also mark 2D bar codes with text/graphic input available.

Minimum character size: 1mm

Ready to Experience the Triangle Difference?

Experience the superior quality of the Triangle Engineering process for yourself. Contact us today to let us know how we can help with your next project.